- +91 95576 18775

- +91 85115 25161

- skengineering9557@gmail.com

How Do C Type Elevator Machines Handle Delicate Food Products Efficiently?

How Do C Type Elevator Machines Handle Delicate Food Products Efficiently?

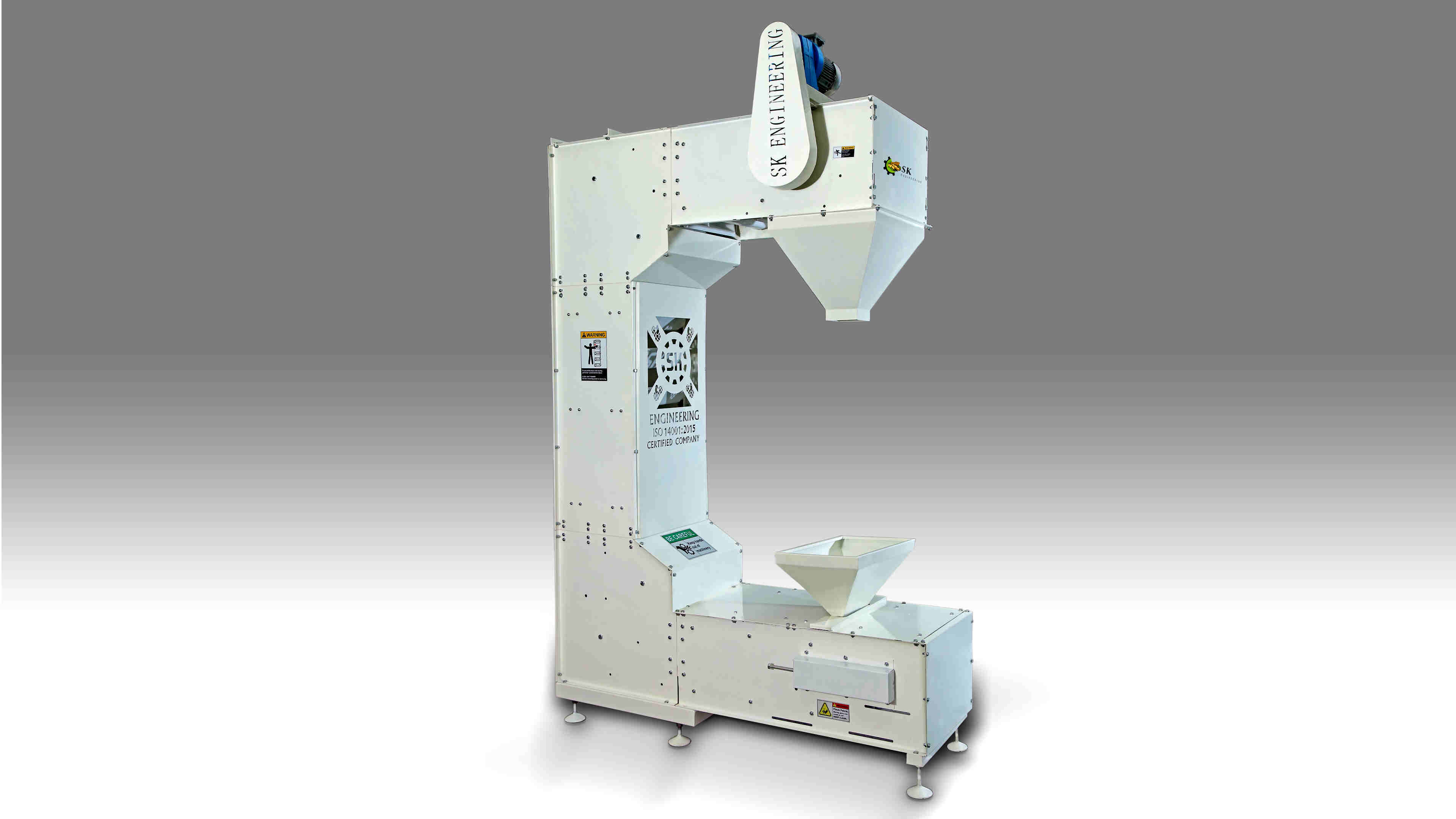

C-Type elevators for food products are known to be revolutionary products that are particularly helpful for industries dealing with fragile food products. These products like that of nuts, seeds, and other food items along with delicate snacks often need such elevators for efficient handling while preserving their integrity.

Before the usage of elevators, the handling of such food items has always been challenging. There has been an advancement of the C-Type Chain Bucket Elevators in India that has provided an optimal solution.

Let us also explore how these machines are designed to address the challenges of delicate food handling while ensuring higher efficiency.

What is a C-Type Bucket Elevator for Food Products in India?

C-type elevator machines have become indispensable for food dispensing and processing. These products are designed in a way to handle dried nuts, fruits, as well as snacks. These elevators are known to maintain the quality and integrity of the food during processing. Food processing machines are responsible for elevating the CAGR by 4% from 2024 to 2030. This is huge!

However, please note that the key challenge is always to maintain delicate food products under a proper preservation schedule and maintain higher operational efficiency at the same time. The key challenge is in transporting the delicate food and preserving its integrity for a longer time.

Conventional methods of handling food products might also lead to loss of structural integrity and damage to the product. However, on this note, an innovative C-type design machine is known to minimize such risks and provide a seamless organic environment for modern food business.

Efficient handling is critical in today's fast-paced and low-time coverage food industry products. Any compromise in the quality of foods might lead to customer dissatisfaction and financial losses. Moreover, it has been found that automatic products reduce damages in products by around 40%, this is good as more food products are available for selling.

C Type Chain Bucket Elevator in India has been specifically designed to overcome these hurdles in the long term. Transportation of such food items is especially crucial for proper and efficient handling of the same.

Key Features of C Type Chain Bucket Elevator for Food Processing in India

Now, let us take a complete look at the C-type elevator machines and see the striking features that make them especially unique. Some of these features are as follows:

1) Bucket Design

A C-type elevator for food products is known to consist of a bucket design, which plays a key role in safe and secure transport. Using these types of spacious buckets is also known to be especially important as it helps reduce crowding, which is often the reason for initiating further damage as well.

Gentle contours and smooth surfaces are one of the primary reasons to minimize the risk of bruising or crushing fragile items like dried fruits and biscuits.

2) Food Grade Materials

Hygiene is always one of the top priorities in the food industry, and the buckets used in these are always made from food-grade quality as well. Stainless steel and specialized materials are also often used to ensure compliance and maintain the highest safety standards. It also helps in preventing contamination and preserving the freshness of the food items as well.

Therefore, it is always good to use food grade quality for better retention of freshness and purity of food products in the long run.

3) Controlled Elevation

Smooth movement and sudden jerks or abrupt stops are always used during elevation, as they can cause significant damage. The controlled elevation is also known to ensure smooth and steady movement that protects the integrity of fragile food items. Moreover, one of the top features of these machines is that they have adjustable speed settings.

Take an example where the nuts can tolerate moderate movements, whereas products like chips require a comparatively gentle movement. Thus, in such conditions, the use of adjustable speed settings allows the operators to customize the performance of the machine to meet its needs.

Therefore, with proper handling of the product and controlled movement, it is used to enhance the versatility of the food products in the long run.

4) Modular Construction

One of the top features of these C-type elevators for food products is that they have a proper modular design that is used to process complex food products. The modular construction of the elevators can easily be installed in various layouts without any significant changes.

This flexibility helps businesses optimize their production lines without losing out on space or efficiency. Modern machines like such bucket systems are known to be only 80-90% effective but it is going to change soon.

5) Hygienic Materials

The non-rusting, food-grade material ensures that the hygiene level remains high. The smooth material does not create too much wear and tear. Moreover, it is non-contaminating in nature, so the product inside is safe to consume.

How C Type Elevator Machines Handle Delicate Food Products?

1) Smooth Loading and Unloading

• Gradual Loading Techniques:

Fragile foodstuffs break up in the process of loading. The above types of elevators use gradual loading techniques, which allow very minimum shocks to be absorbed by the product; hence, it does not break as it moves around.

• Controlled Discharge Mechanisms:Unloading food products is a sensitive operation, particularly for fragile goods. The controlled discharge mechanisms control the flow of the products when unloading so that there are no sudden drops or collisions, which can compromise the quality of products.

2) Delicate Bucket Movement

• Chains or Belts:

Chains or belts are used in such elevators to ensure smooth flow and consistency. Unlike the usual systems, which can show vibrations or jolts, these mechanisms assure steady flow and protect delicate food items.

• Minimization of Sudden Stops or Starts:Sudden movements tend to strain the product as well as the machine. In this context, these elevators reduce wear and tear while allowing for the safe transportation of food products by minimizing sudden stops and starts.

3) Reduction in Vibration

• Advanced Engineering:

The vibrations that accompany transport cause damage to delicate products such as chips or biscuits. The elevators are engineered using the finest technologies of advanced engineering so as to absorb and dampen down vibrations and make handling a lot softer.

•Impact Absorbers:Even more impact absorbers are provided to ensure that even the most delicate of products arrive at the destination in perfect conditions.

4) Speed and Inclination are customizable

• Adjustable Speed:

The operator can better control the handling process through adjustable speed settings. Fragile products are transported at slower speeds and are thus safely transported.

• Angled Design:Such elevators are designed as angled ones so smooth product flow can be attained without the accumulation of blockages and some unexpected drops. This feature is very helpful in the case of items like nuts and dried fruits, which always require smooth and gentle handling.

5) Maintaining Product Integrity

The priority in food processing involves the shaping and texture preservation of fragile articles. Such elevators will be constructed with a design such that their products, therefore, have minimal chances of breakdown or crushing during handling.

6) Productivity

It would make a high degree of efficiency achievable through automation. Automated food product transport helps to save on otherwise laborious handling and thus reduces time in elevators, thereby saving time and labor costs.

7) Improved Hygiene

Hygiene cannot be compromised in the food industry. The design of such elevators reduces human contact with the product, which reduces the risk of contamination. Food-grade materials make it even cleaner, making sure that products are safe for consumers.

8) Versatility

One of the most excellent characteristics of these machines is adaptability. Be it wild candies, biscuits, or chips, C Type Bucket Elevators for Food Products handle everything with a smile; therefore, these are useful for any food processing factory.

Industries Satisfied with C Type Elevator Machines

The use of C Type Chain Bucket Elevator in India has really benefited many different types of industries:

• Confectionery and Snacks:Fragile candies and snacks have a very fragile form and appearance and have to be treated with great care. These elevators fulfill that requirement.

• Nut and Dried Fruit Processing:Nuts and dried fruits are highly breakable. Smooth transportation is facilitated by these elevators to retain the quality of high-value products.

• Bakery and Pastry Production:From delicate pastries to biscuits, the elevators handle a wide variety of baked goods delicately and with care.

• Frozen Food Handling:Frozen products are usually handled differently. The adjustable parameters of these elevators ensure that frozen foods are handled without losing their quality.

Technological Innovations of C-Type Elevator Machines

1) Smart Controls

• Automated Sensors:

Modern elevator machines have sensors that scan the load levels continuously and operate in real time. It not only increases efficiency but also prevents overloading for the safety of the machine and the products.

• Integration:There is a smooth operation, and because the other machinery can easily work with it in the production line, it enhances general productivity.

2) Noise Reduction Technology

High operation noise in food processing centers creates a major issue. Higher technology for noise abatement makes working conditions quieter; therefore, the workplace will be easier for staff workers.

3) Energy Efficiency

This is a harsh problem associated with industrial activities concerning energy usage. They construct elevators with energy-cutting motors, and these motors utilize relatively fewer amounts of power without neglecting the services. Therefore, these elevators are productive as well as environmentally friendly.

Working Tips for Proper Operation

Proper maintenance is essential for the long-term durability and efficiency of C Type Bucket Elevators for Food Products. Follow these tips to ensure optimal performance:

• Regular Cleaning:Prevent residue buildup that may compromise hygiene and efficiency. Cleaning should be carried out regularly to keep food-grade materials clean.

• Inspection:Bebelts, chains and buckets were inspected for wear and tear to prevent breakdowns that do not come in sight. Early detection of problems saves time and money.

• Lubrication:Move parts are lubricated with the intention of smooth and gentle running of equipment. Proper lubrication cuts friction and serves the life of equipment in a better way.

Read More: Top 5 Benefits of Using a Vibro Destoner in Your Processing Plant

Conclusion

The modern food processing industry has a paramount emphasis on the preservation of sensitive food products. Advanced design and functionality make C-type bucket elevators for food products in India a necessity that no industry can do without when it comes to efficiency and hygiene.

Investing in such machines would help businesses streamline operations while ensuring the highest standards of quality for their products. From nuts and dried fruits to snacks, such elevators offer performance levels that cannot be compared, making them a good choice for any food processing facility.

Read More: The Future of Indian Agriculture: Multi-Commodity Processing Technology at Work